Injection moulding is a key manufacturing process for many items, from everyday goods such as home appliances and mobile phones, to large engineering parts such as car bumpers.

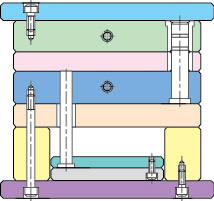

A mould base can be described as a collection of machined steel plates combined with components. It forms the basic framework of the mould. A mould maker can purchase a mould base, carry out further tooling and turn it into a production-ready mould. The illustration at the top of this page shows a typical mould base.

While the description is relatively simple, the importance of a mould base should not be underestimated. The precision of these machined plates and components has significant effect on the overall precision of the mould, and quality of the final product. For plastic parts such as medical devices, micron level precision is required.

The production process and equipment required for production of mould plates from raw materials are very different from those used in the final tooling process of a mould. Thus in general a mould maker will prefer purchasing a ready-for-tooling mould base, than to build one from scratch. Indeed, very often, a mould maker will request further machining work on these plates before delivery.

The mould base industry is a very developed market. Mould makers can choose from a wide range of products to suit their specific project needs. Those who prefer time and cost efficiencies can purchase "off-the-shelf" standard mould bases, such as the LKM Standard Mould Base Series. While those who with limited machineries can order a custom-made mould base, which are produced to the exact customer's specifications.